Process Mining vs Process Modeling: Two sides of the Same Coin

When it comes to process transformation, you need both a strategy and a clear understanding of where you are today. That’s why process modeling and process mining are critical to your success.

To remain successful in a competitive, globalized world, every organization needs to undergo constant transformation in the way they do business. Change and innovation are a part of the new normal for businesses across all industries. These practices can range from small—like making shifts to meet new market demands or industry regulations—to implementing larger customer-focused business model innovations that can disrupt the underlying industry or even create an entirely new market.

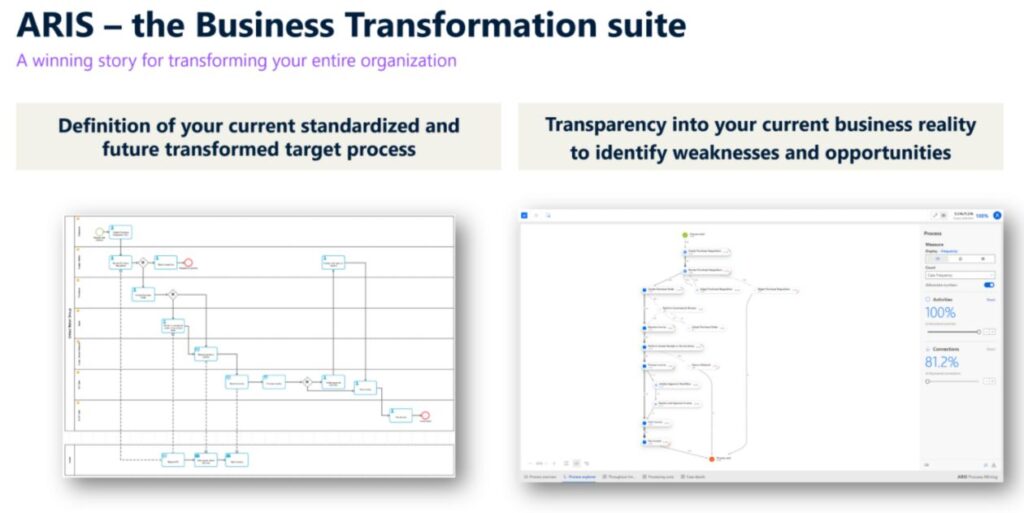

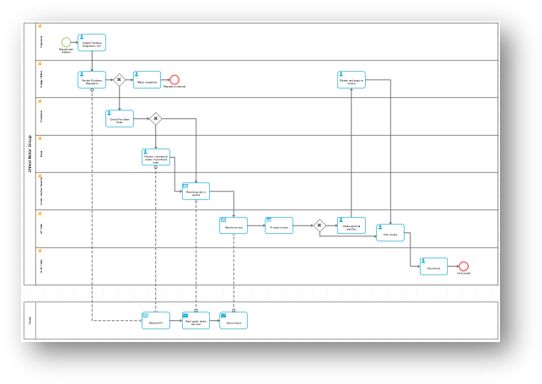

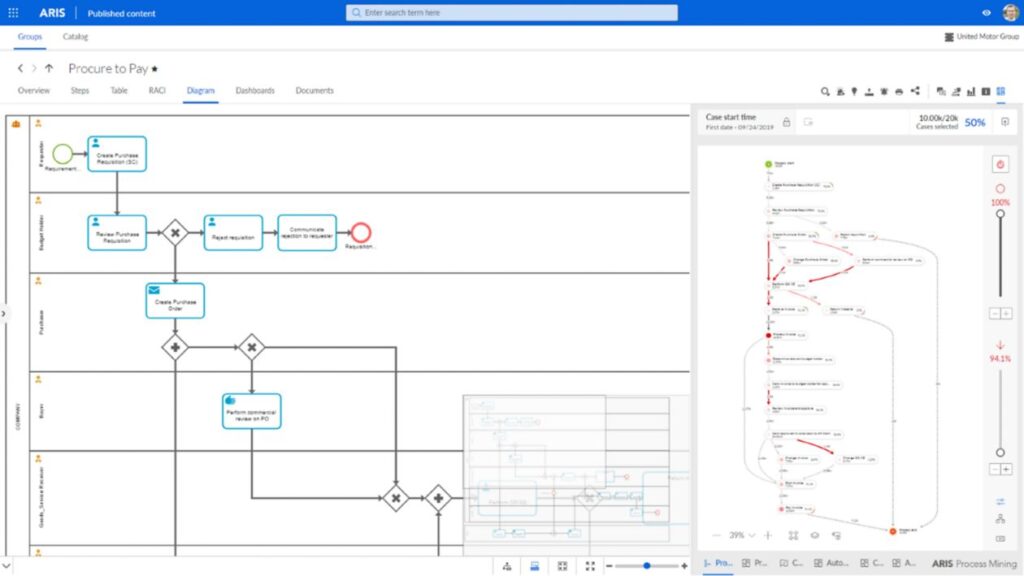

To transform YOUR organization, you essentially need two components: a) a strategy and plan for the desired new way of working, and b) crystal-clear visibility into your current modus operandi. In the case of digital transformation, (a) is process modeling, which sets the bar you want to achieve, and (b) tells you where you are and what you need to change using process mining to achieve (a).

It’s like two sides of the same coin—you need both to actually pay with it…

Get insight into current operations using process mining

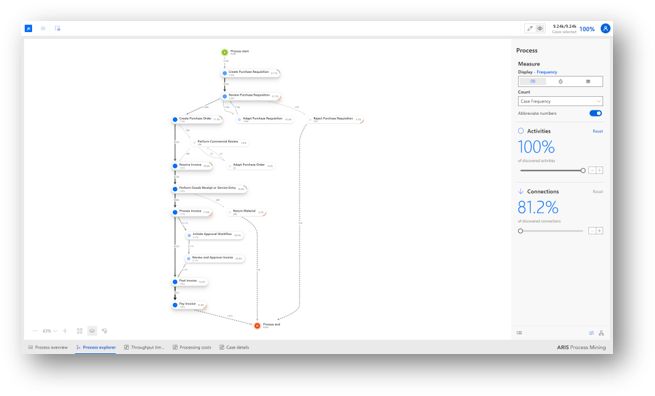

Process mining allows you to take all the process data within your company and “mines” it for insight on potential improvement, focusing on finding better, more efficient pathways in operations. The goal is to take a deep-dive into as-is processes and discover “touchless” process paths that require minimal human intervention and increase the speed, accuracy, and quality of whatever your business does.

So what can process mining reveal about a business’s current state of operations?

Let’s take a process from order to delivery as an example. Customers today demand a highly flexible and digitized customer experience that allows them to change their order up to the last possible moment. When customers cannot do this because of inefficient processes, businesses risk losing customers to a competitor.

Here’s an example: I recently ordered some clothes from a large fashion house and wanted to change the size of one of the items after I placed the order. The process model used by the designer could not support my request to change the size of one piece of clothing AND my request caused issues with the shipping and delivery of the entire order. It was a nightmare experience for me as a customer, and from a sustainability standpoint, it created a lot of waste.

In this case, process mining could help this business identify those touchless points in the process that can be improved to deliver an improved customer experience and reduce waste. Maybe the data analysis will reveal that a tweak in the point-of-sale software can support a customer’s ability to amend an order within a certain timeframe without causing delays. Or maybe it will identify opportunities to increase efficiencies in the shipping, deliver, and return steps of the process which will lead to increased customer satisfaction. These are only assumptions, however. A complete process mining analysis can only reveal the realities of a business’s as-is state.

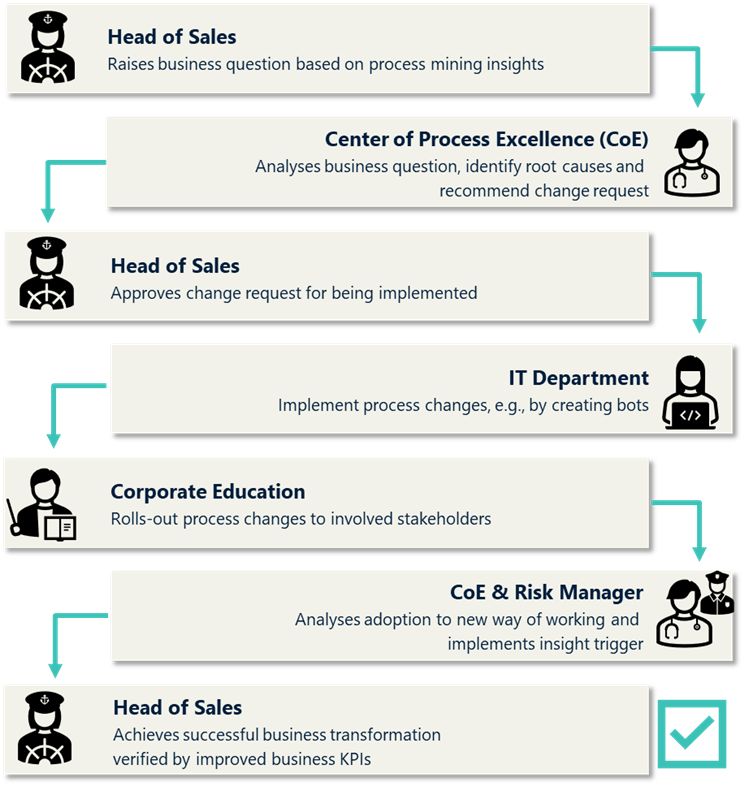

- The Head of Sales may be wondering about a drop in customer experience (e.g. measured by the Net Promoter Score or NPS) or an increased return rate, and turns this issue over to a Center of Excellence (CoE) to determine the root cause of the changing KPIs.

- The CoE determines the customer’s need to change placed orders, analyzes how inventory management processes need to be changed and what IT systems (e.g., customer-facing mobile apps, online store websites, customer support applications) need to be updated to handle the changes. They then model how the underlying process can be redesigned—setting the bar for the transformation.

- The recommended changes are submitted to the Head of Sales for approval.

- Once approved, the IT department (and physical warehouse teams) can implement the required changes.

- Then, the Corporate Education department uses the digitalized process descriptions to effectively communicate the changes to the stakeholders involved, because if only the underlying IT systems are changed without ensuring that everyone involved in the process is aware of the latest changes, the transformation will cause friction or even worse.

- The CoE can monitor whether the new way of working is being adopted by employees and IT, or whether some sales channels (e.g., mobile shopping) or countries are having difficulty with the changes and require further IT implementation or training.

The flip side of the same coin: Process modeling

Order changes are increasingly a necessity not only in the stock-to-order business, but also in make-to-order. Take automotive manufacturers, who must allow customers to change their vehicle configuration until extremely late in the production process, like changing the paint color by the time it reaches the paint shop. Customers also demand full visibility into their orders. This applies not only to automotive orders—which can take many months to more than a year in times of global value chain disruption—but to industries with shorter make-to-order timelines like the live tracking of food deliveries.

Once you’ve acquired the data and insights into how your business operates, the next step is critical to achieving the innovation you want to see throughout your business model: process modeling.

“…removing silos and encouraging the free flow of information is what drives innovation, change, improved efficiencies, all things that ultimately make a truly connected enterprise.”

Process mining and process modeling are often thought of as two unrelated practices used for digital transformation. I would argue that in actuality, they are very closely related and are in fact, two sides of the same coin.

You can’t successfully accomplish a process modeling exercise without the data and insights derived from process mining. That seems like an obvious statement, but you would be surprised at the number of customers I work with who treat process mining and process modeling as siloed entities within their transformation journeys. And if there’s anything we know better at ARIS, it’s that removing silos and encouraging the free flow of information is what drives innovation, change, improved efficiencies—all things that ultimately make a truly connected enterprise.

If you want to change the way you do business, or even your entire business model, to achieve the innovation you want, there are many stakeholders involved. Therefore, you need a platform that manages the transformation process AND delivers the right information to the right people at the right time. Take the process from order to delivery as an example: If you only change the underlying IT systems without educating everyone involved in the process on those changes, the transformation will cause friction or even worse.

ARIS—the transformation suite

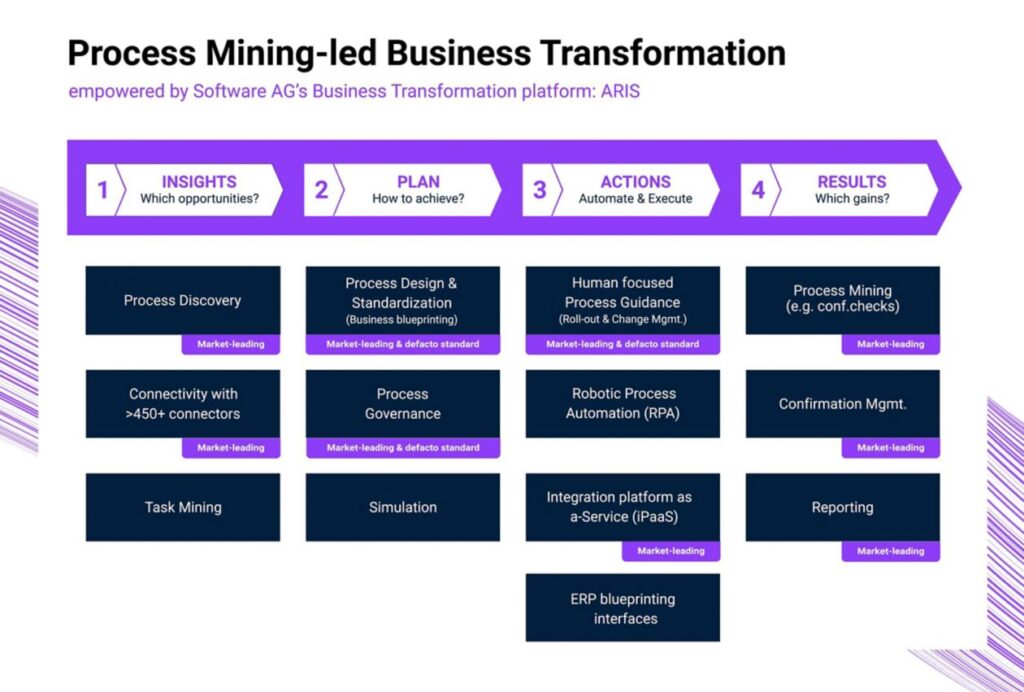

To successfully drive your transformation, our ARIS suite provides you with all the essential ingredients.

In the past, it was unfortunately common in many organizations to either focus on documenting processes or mining them, which often led to failed transformations or at least less effective change processes. Surely this is not a surprise, because you don’t want to be a transformation pirate, shipping your organization’s transformation one-eyed.

While an increasing number of companies have already implemented process modeling and mining, the majority still do so in isolation, resulting in lower effectiveness of transformation outcomes or even failed approaches. This is similar to companies working in isolated functions rather than process-driven organizations.

For true transformation heroes, it will therefore become best practice to establish an integrated transformation platform to gain fact-based, data-driven process insights as well as planning and rollout capabilities to turn plans into actions and ultimately measurable results.

And stay tuned—more to come soon.

With ARIS as a platform with a full 360-degree coverage of transformation capabilities, we can deliver exactly the right suite for you as a true transformation hero. You will have everything you need to lead your business into a sustainable and bright future.

ARIS

And that’s not all: ARIS helps you become a truly connected enterprise thanks to our leading application and data integration capabilities. These are key for the success of process mining! You not only need standard connectors for business applications, for which we offer hundreds, and solution accelerators to speed up the onboarding of standard processes, but also true integration capabilities for specialized or homegrown applications. This is especially important for order-to-cash processes where customer journey innovation is key, as described above: customer-oriented applications are often proprietary developments for which no standard adapters can exist. Therefore, trust us and become a true transformation hero in your truly connected enterprise.